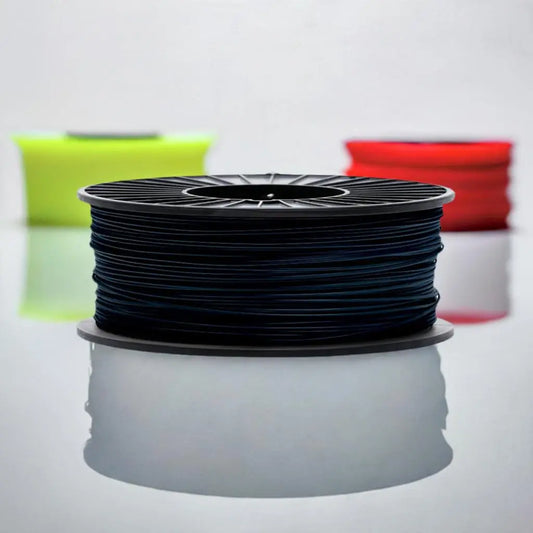

I've been using COEX filament for many years and have visited their plant twice. Very friendly and welcoming. The quality has always been consistent and reliable. The Mystery PLA spools are a great bargain. Sometimes interesting colors, sometimes bland but useful for prototypes. Grab these especially when they are on sale - you will not be disappointed.

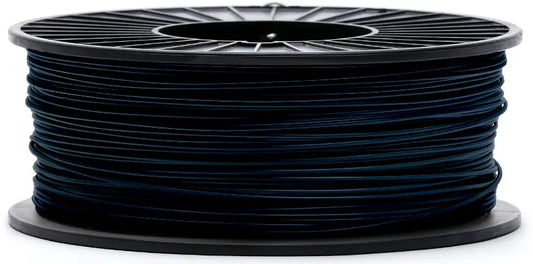

UV reactive and just adorbz. i love this material. everything i make with it gets compliments. its the bees knees

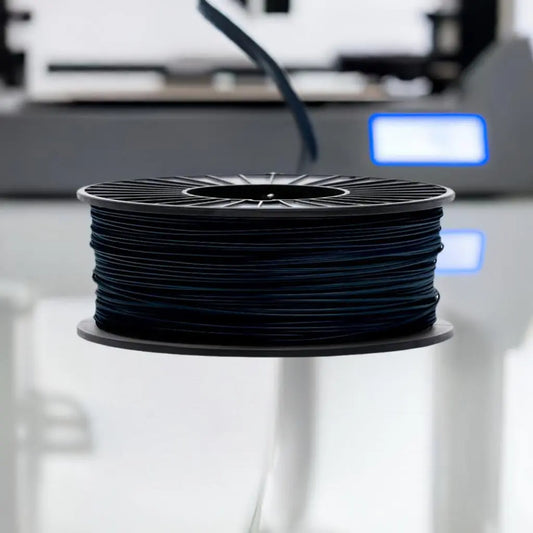

Unfortunately I won't be ordering anymore.

Worked well once I got it dialed in.

Big part of my decision is be cause of the spools. Tired of fighting them in my bambu ams.